Joalo ka ha bohle re tseba, Terminal Block ke mofuta oa sehokelo.Lenaneong la khokahanyo ea motlakase oa motlakase, ponahalo ea Terminal Block e ka boleloa hore e lokolla matsoho a basebetsi ba tlhokomelo.Terminal block e na le melemo ea sebopeho se bonolo, mefuta e fapaneng le ts'ebeliso e bonolo.Haholo-holo ha ho hloleha ho qetela, phetolo e bonolo haholo, feela ho hlokahala hang-hang ho tlosa phetolo e mpe ea terminal ea mofuta o tšoanang oa litekanyo tsa terminal e ncha e ka ba, haholo ho fokotsa nako ea tlhokomelo.Mokhoa oa ho hokahanya oa "terminal block" hangata o arotsoe ka mefuta e mehlano.Mona ke ho e hlalosa ka hloko.

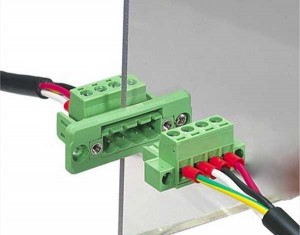

[ Screw connection ]

Screw connection ke mokhoa oa ho hokahanya oa "screw type block block".Ho kgothaletswa hore o ele hloko karolo e ka holimo le e fokolang ea sefapano sa terata e lumelletsoeng e kopanyang le matla a maholo a ho sotha a li-screws tse nang le litlhaloso tse fapaneng.

[ Welding ]

Mofuta o tloaelehileng ka ho fetisisa oa ho cheselletsa ke oa lipekere.Ntho ea bohlokoa ka ho fetisisa ho hokahaneng ha soldering ke ho tsoela pele ha tšepe pakeng tsa thepa ea soldering le holim'a welding.Kahoo bakeng sa block ea terminal, terminal e hatelletsoeng ka serame, senotlolo ke solderability.Liaparo tse tloaelehileng haholo lipheletsong tse soldered tsa li-terminals ke thini, silevera le khauta.Mofuta oa ho kopanya lehlaka o na le mofuta oa ho tjheseletsa, mofuta oa ho tjheseletsa oa mahlo le mofuta oa notched oa welding: pinhole contact pair e na le mofuta oa ho cheka oa arc notched qetellong ea welding.

[ Khatello ]

Clamping ke mokhoa o sebelisoang ho honyela le ho khelosa thepa ea tšepe ho isa tekanyong e lakatsehang le ho hokahanya terata ho para ea ho kopana.Molemo crimping kgokelo ka etsa hore thepa tšepe ho qhibiliha mong ho e mong phallo tse ling tse, e le hore terata le ho kopana ka e tala thepa symmetrical deformation.Mofuta ona oa khokahano o ts'oana le khokahanyo e batang ea welding, ka bobeli ba ka fumana matla a matle a mochini le ts'ebetso ea motlakase, e ka mamella tikoloho le litlhoko tse thata ho feta.Mothating ona, ho lumeloa hohle hore khokahano e nepahetseng ea crimping e betere ho feta tjheseletsa ea tin, haholoholo libakeng tse kholo tsa phallo ea hajoale e tlameha ho sebelisoa sehokelo sa crimping.Ha o tobetsa, ho lokela ho khethoe lisebelisoa tse khethehileng tsa ho hatisa kapa mochine oa khatiso o itekanetseng kapa oa semi-automatic.E lokela ho ba e thehiloeng batang petelitsoe terminal, batang petelitsoe terminal terata karolo, tšebeliso e loketseng ea ho kopana le terata tube.Hlokomela hore khokahano ea crimping ke khokahano e sa feleng, ka hona e ka sebelisoa hanngoe feela.

[ sephuthelo sa terata]

Mohala oa maqeba o koaheloa ka kotloloho holim'a kholomo ea leqeba la ho kopana.Ha terata e e-na le leqeba, terata e etsoa tlas'a boemo ba hore tsitsipano e laoloe, 'me e hatelloa ka hare le ho ts'oaroa ka mathōko le likhutlong tsa leqeba la karolo ea ho kopana, e le hore e thehe ho kopana ha moea.Ho na le litokisetso tse 'maloa bakeng sa terata ea leqeba: bophara ba terata bo tloaelehileng bo lokela ho ba ka har'a sebaka sa 0. 25mm ~ 1.Ha bophara ba mokhanni bo sa fete 0.5 mm, matla a khoheli a thepa ea mokhanni ha a ka tlase ho 15%;Matla a matla a lisebelisoa tsa mokhanni ha aa lokela ho ba ka tlase ho 20% ha bophara ba mokhanni bo feta 0.5 mm.Lisebelisoa tse tsoelipanang li kenyelletsa sethunya se tsoelipanang le mochini o tsoelipanang o emeng.

[ Hlakola khokahano ]

Khokahano ea liphaephe e bitsoa khokahano ea "insulation displacement connection", e qapiloe ke United States ka bo-1960 theknoloji e ncha, e nang le ts'epo e phahameng, theko e tlase, e loketseng ho sebelisoa le litšoaneleho tse ling, e 'nile ea sebelisoa haholo mefuteng e fapaneng ea li-terminal tsa boto tse hatisitsoeng, khatello e batang. li-terminals, li-terminals.E loketse ho hokela thapo ea lente.Ha o hokahana, sheath ea thapo ha e hlakoloe, empa pheletso e bohale ea "U" ea sebopeho sa terminal e amanang le lehlaka e phunyeletsoa ka har'a sheath ea cable, e le hore mokhanni oa thapo a kene butle ka har'a groove. e kopana le lehlaka 'me e tlameletsoe, kahoo e hlahisa khokahanyo e ke keng ea arohana ea motlakase pakeng tsa conductor ea thapo le lehlaka la terminal.E hloka lisebelisoa tse bonolo feela, empa e hloka mohala o nang le terata e behiloeng.

Nako ea poso: Apr-21-2021